Laser Samping:Materials can be carried out on the actual paper-box-type design sampling,the relative mechanical sampling, because there is no cont-act pressure,a more accurate and faster,and equipment investment costs,day-to-day with alower cost than mechanical Proofer

Laser Mapping: Mapping single map or large-format print onto a layout diagram paper, one can save a few million Units of large format plotter, as printing the drawings and actual knife mold cutting use the same machine, this can avoid precision inconsistency error between different devices, it?/FONT>s higher accuracy, and can do off-line job

Laser Cutting: Using the exclusive patented technology able to cut production of 5mm, 6mm plastic knife mold and 18mm, 15mm, 20mm wooden knife mold, can cut such as 0.45, 0.53,0.71,1.05,1.42 mm and other width kerf.

Minimal investment: compare to other machine have relative functions which will cost millions dollars from abroad or nearly million yuan from domestic, this product just takes over ten thousand yuan, little investment, cost-effective, extremely small risk, fast return, three to six months will recover your investments.

Efficient: cutting speeds up to 150 meters / day (18mm board) to 500 meters / day (6mm plastic), monthly output can reach 10 million, one machine can meet most of knife mold factory who has the packaging/printing plant's needs.

Very low consumption: 24 hours of continuous work every day to work 30 days, fees for utilities, expendable components (laser tubes, lenses, etc.) just cost less than one thousand dollars per month, only take one to several presents that of other import laser knife mold cutting machine, plug and play, without boot time ?

One station Service: Free training, free shipping to install, free of charge for one year warranty, free upgrade, life-long maintenance.

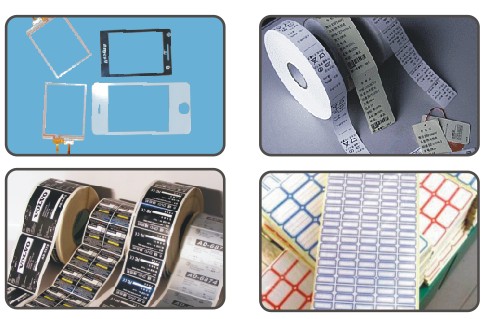

Application Industries: clothing, leather, advertisement decoration, crafts gifts, paper products, wood products, lighting, packaging, plate making, and daily necessities, model, shadow carving, such as digital phase under the basket knife mold cutting, self-adhesive knife mold, cutting the screen.

Applicable materials: all kinds of textile fabrics, synthetic natural leather, plastic, PVC type, paper, wood, rubber, resin, etc..

Industry uses: clothing embroidered patch, trademark precision cutting; garment accessories carving high-precision, drilling, trimming; leather punch, lofting, the materials; plexiglass, plastic, PVC type, paper products, such as precision cutting; fargesii , which has affected the industry, such as carving Express high-precision carving, knife mold production, self-adhesive, wood cutting boards, electronic boards.

|

Model |

AL-0906-T/AL-1206-T/AL-1509-T |

|

Laser power |

60W 80W 120W |

|

Job area |

(900X600)mm/(1200X600)mm |

|

Cutting speed |

24000mm/min |

|

Minimum word |

1mm |

|

Positioning accuracy |

±0.01mm |

|

Environmental Insulation |

0~45℃ |

|

Supported formats |

PLT、BMP、 DXF、 DST 、DWGHPGL |

|

Power |

AC220V±5%,50HZ |

|

Dimensions |

(1760X1160X1000)mm/(1660x1160x1000)mm |

|